Chinzombo Lodge site is an ecologically sensitive region within a national wildlife conservation park, which required any construction to be environmentally friendly, minimise physical impact during construction and ensure longevity to prevent unnecessary future upgrades or maintenance.

PROJECT DETAILS

- Project Name Chinzombo Lodges

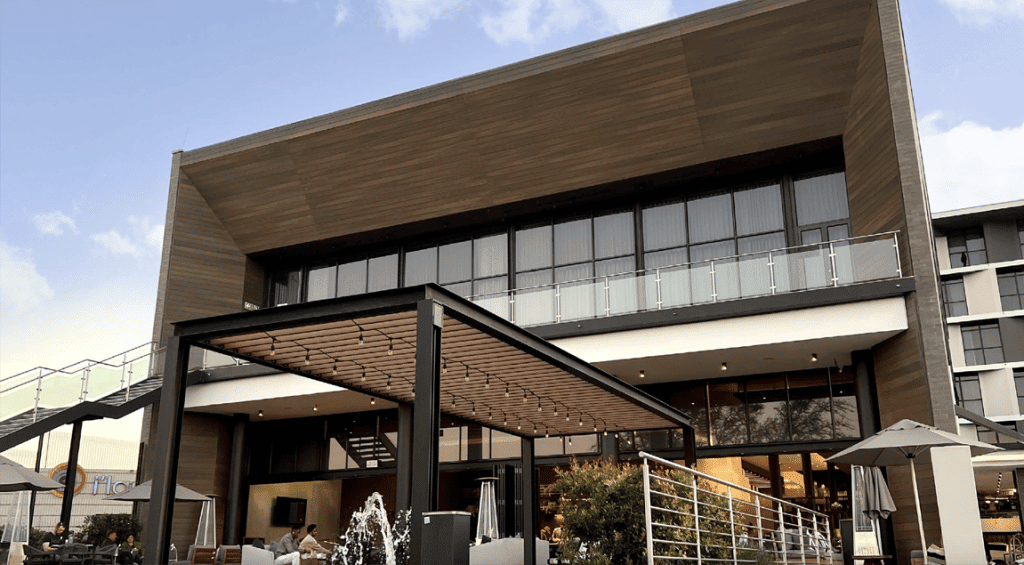

- Project Type Decking, flooring and fascias

- Description Composite decking and fascia boards used to create luxury tented camp infrastructure and shells, as well as communal entertainment area.

- Size +/- 1500 m2

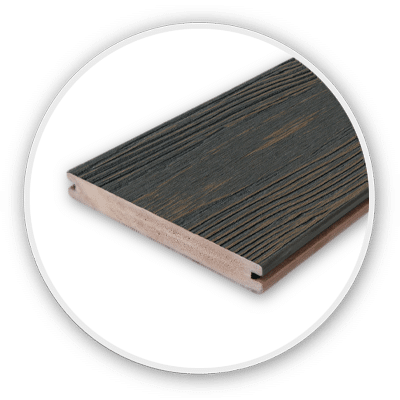

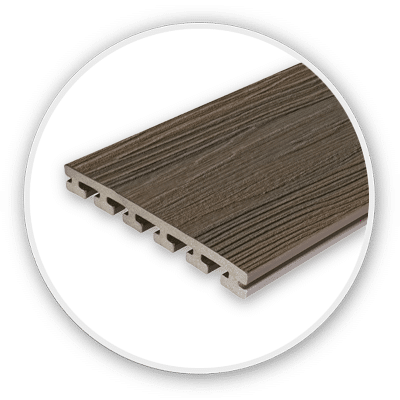

- Product Eva-tech

- Date of Installation 2012

- Project Location : Time + Tide Chinzombo Lodge, South Luangwa National Park Zambia

- Architect Silvio Rech & Lesley Carstens

- General Contractor Bluegreen Limited

PROJECT CHALLENGE

The architect’s design brief was to create a fully sustainable, environmentally friendly group of identical villas and communal entertainment area for guests. Each villa was built to provide a 150m2 deck on which a bedroom, bathroom and partially covered outdoor relaxation area with a fibreglass pool would be placed.PROJECT SOLUTION

The lightweight structures of each villa and the communal entertainment facility were all constructed of steel, heavily treated pine trusses to raise the decking base off the ground and Eva-tech decking and fascia boards. The external walls and bathroom enclosures were created using both locally sourced grass, reeds and tent fabric, suspended from Klip-Lok roofing.Chinzombo Lodge villas and communal building were designed to be fully and easily dismantlable, leaving little to no impact on the area. Materials were specified to ensure longevity and durability to reduce future modifications, repairs and maintenance. Eva-tech’s environmentally friendly credentials and high durability performance ratings were the factors taken into account in selecting these materials.

Despite being exposed to all weather conditions and a high level of heat, rain and dust at certain times of the year, the Eva-tech natural timber finish requires only cleaning to maintain its appearance

RESULTS

In alignment with the lodge’s low-impact ethos, local residents were employed to complete assembly of the construction components which had been manufactured in South Africa and transported to Zambia. Without prior working experience with Eva-tech, under the guidance of a single foreman, the team of workers were able to complete each villa within five daysKEY INFLUENCER QUOTE

Since installation in 2012, the Eva-tech decking and fascia profiles have performed optimally in harmony with the surroundings.The client is very happy and we’ve used the same materials and techniques for various other lodges in Zambia and Madagascar – the only thing that has changed is the selection of aesthetic finishes to account for local environmental conditions. The Eva-tech profiles we used have been in place for nine years and are still going strong. – Alex Hardy, Bluegreen Ltd.

SUMMARY

Eva-tech decking and fascia boards were selected to complete an environmentally friendly, durable luxury lodge in a Zambian national park. All materials and construction methods were specified to ensure that the lodge was sustainable with little to no impact on the surrounding ecology.Eva-Last is a globally recognised and trusted brand that manufactures and distributes specialised bamboo-plastic composite building products.Together with a wide range of decking, cladding and flooring products, Eva-Last also offers specialised support systems and expert advice, ensuring each and every build is designed to last. Eva-Last composite profiles and complimentary systems can be found in over 35 countries globally and have been an imperative part of some of the world’s largest building projects. As the leaders in composite building technology, Eva-Last ensures product quality and customer satisfaction with industry and class leading warranties.

Click here to download a PDF version of this case study.