Technological advancements in composite building materials have had the effect of constantly raising the baseline for performance and aesthetics. Those composite products that no longer perform to a certain standard are made obsolete. It is tough to maintain a prominent position in the African market, but Eva-Last’s Apex range continues to lead thanks to its aesthetic qualities and performance characteristics, underpinned by a 30 year warranty.

The engineering behind Apex, designed in South Africa, created an acrylic polymer capping with an ultra-lightweight foamed bamboo-PVC composite core, making workability incredibly versatile and reducing installation time. Apex provides decay and weather resistance; resisting mould, insects, moisture and weathering. However, what really makes Apex unique is the class leading slip and fire resistance ratings, a differentiating factor in environments that require stringent decking safety standards.

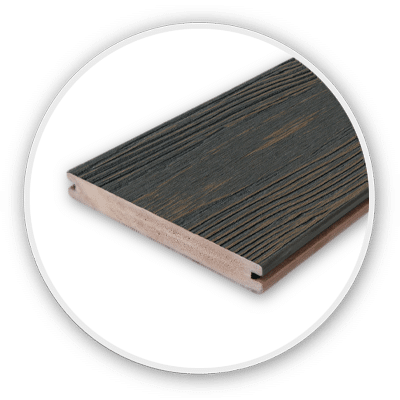

Eva-Last co-founder Nathan Chapman says that Apex is most natural-looking of the Eva-Last composite decking brands.

The engineering behind Apex, designed in South Africa, created an acrylic polymer capping with an ultra-lightweight foamed bamboo-PVC composite core, making workability incredibly versatile and reducing installation time. Apex provides decay and weather resistance; resisting mould, insects, moisture and weathering. However, what really makes Apex unique is the class leading slip and fire resistance ratings, a differentiating factor in environments that require stringent decking safety standards.

Eva-Last co-founder Nathan Chapman says that Apex is most natural-looking of the Eva-Last composite decking brands.

“The incredibly natural looking finishes belie their real qualities as environmentally friendly alternatives to timber that use holistically sustainable raw materials and eco-friendly manufacturing processes.”

Chapman says composite decking materials come into their own when considering long-term performance and superior design to natural timber. “With a EUROCLASS Bfl – s1 fire resistance rating, Apex would be an obvious choice over timber in any fire risk area. There are many qualities that outperform natural timber that are invisible until certain conditions are present. This is where world-class design can not only save the environment but create a host of performance benefits.”

Another modern engineering contribution to Apex’s longevity is the ability to offer a customised Hulk Fastener hidden fixing system that lasts as long as the deck. Utilising the Chain collated decking clips product, provides a seamless, neat and clean finish to any decking project.

“Fasteners have also come a long way from traditional nails and screws, with Hulk Fasteners optimised to accommodate the natural expansion and contraction of boards while never losing their secure grip – which they do completely hidden from view. Installations have also become incredibly streamlined and quick, producing finishes free from blemishes, rips, tears, or splinters in minimal time,” Chapman adds.

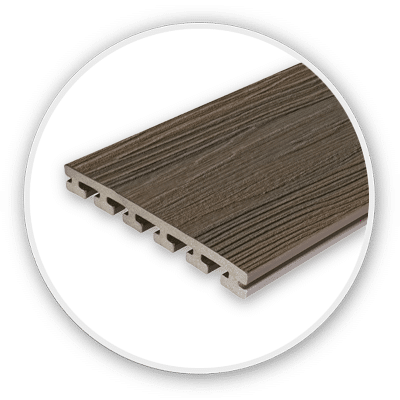

Available locally in single-sided grooved decking boards, starter boards for edging and picture framing, square-edged boards for staircases and breaker boards and fascia boards for matching trims. The Apex range also features a composite joist profile as a cost-effective option for use over existing slabs such as screed or tile flooring, paving and patios. Apex allows for an array of product possibilities – all with the same world-class engineering behind them.

“The Apex dual tone colouring adds blended colour layers to each board to enhance the natural look. The variance in shades within a single composite profile beautifully represents the colour tones found in timber, making the installation more striking, and with Apex’s fade resistance in all settings, the installation will go on performing as it did on day one, for decades to come,” says Chapman.

Another modern engineering contribution to Apex’s longevity is the ability to offer a customised Hulk Fastener hidden fixing system that lasts as long as the deck. Utilising the Chain collated decking clips product, provides a seamless, neat and clean finish to any decking project.

“Fasteners have also come a long way from traditional nails and screws, with Hulk Fasteners optimised to accommodate the natural expansion and contraction of boards while never losing their secure grip – which they do completely hidden from view. Installations have also become incredibly streamlined and quick, producing finishes free from blemishes, rips, tears, or splinters in minimal time,” Chapman adds.

Available locally in single-sided grooved decking boards, starter boards for edging and picture framing, square-edged boards for staircases and breaker boards and fascia boards for matching trims. The Apex range also features a composite joist profile as a cost-effective option for use over existing slabs such as screed or tile flooring, paving and patios. Apex allows for an array of product possibilities – all with the same world-class engineering behind them.

“The Apex dual tone colouring adds blended colour layers to each board to enhance the natural look. The variance in shades within a single composite profile beautifully represents the colour tones found in timber, making the installation more striking, and with Apex’s fade resistance in all settings, the installation will go on performing as it did on day one, for decades to come,” says Chapman.